By Maura Mazurowski

As the number of Virginians testing positive for COVID-19 continues to climb, one Fairfax attorney is doing his part to help flatten the curve.

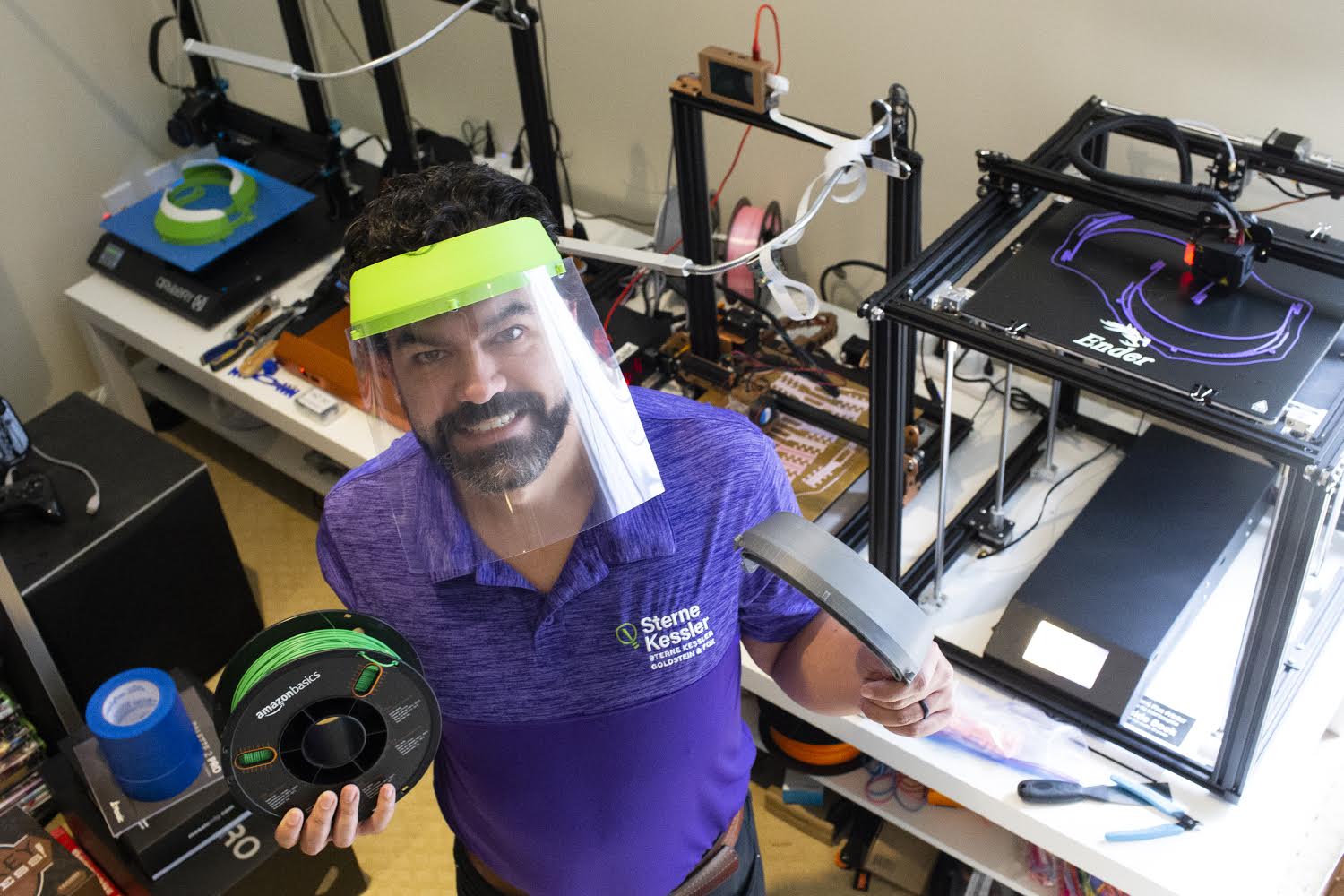

In 2018, intellectual property lawyer Sal Bezos picked up a new hobby: 3D printing. Bezos initially had a technical interest

in 3D printing in relation to his patent practice with Sterne, Kessler, Goldstein & Fox, a Washington-based firm with clients in Virginia and Maryland.

However, as the coronavirus pandemic continued to spread, Bezos saw more and more stories popping up about people

using 3D printers to make face masks for healthcare workers at home.

He decided to give it a try.

“I started with face mask strain relievers, which is basically a clip that, rather than attaching a face mask around your ears, you attach it to hooks behind your head,” Bezos said. “It was easy to print, so I did a handful of those and posted the results to my personal Facebook.”

After posting photos of his work, Bezos said he immediately received messages from friends saying they knew of a number of physician’s offices in the area that could benefit from strain relievers.

“I started delivering them to people… It got me thinking about what else I could make,” Bezos said.

Soon after, Bezos began printing face shields using a clinically approved design he found on the National Institute of Health’s website.

“The FDA has authorized production of protective face shields outside of the normal clearance pathway during the COVID-19 pandemic,” the NIH website reads.

The face shields, which are visually akin to a welder’s mask, do not seal around the face as other types of personal protective equipment (PPE) do, nor have they undergone governmental certification or testing. However, Bezos said they still provide an extra layer of protection for health care providers when treating patients.

“Think of it like a splatter guard,” he said. “If you are intubating a patient, for example, you’re going to come in contact with their fluids. Face shields help prevent exposure to that.”

The antimicrobial masks are reusable and consist of a hard plastic shell housing a replaceable filter. They’re also easy to

clean with soap and hot water, or they can be sterilized with ultraviolet light.

Bezos now has four larger 3D printers working “full-time” to create face shields, with a smaller printer continuing to make strain relievers.

“What I liked about the [face shield] design is that it’s a relaxed process. But in times of emergencies, it’s a very simple design to print out,” Bezos said.

PPE shortage has been an ongoing issue across the country, and Virginia is no exception. Supplies on protective gear were so low that, last month, Gov. Ralph Northam put all elective and nonessential surgeries on hold to conserve PPE for healthcare providers.

As of May 1, elective and nonessential surgeries have resumed.

“We’re woefully short. Numerous requests have been made of our strategic national stockpile and we’ve received a mere

fraction of what was requested. So like other states, we have had to go to the market to find suppliers,” said Brian Moran,

Virginia Secretary of Public Safety.

Since starting the printing process a month ago, Bezos has delivered more than 250 face shields to physicians’ offices and hospitals in the Northern Virginia area.

“My understanding is these medical facilities have kind of relaxed the requirements for the medical professionals to be able to bring in their own PPE, so I’ve actually been delivering these directly to individual contacts who requested shields for themselves,” Bezos said.

Though he enjoys the process of 3D printing, Bezos’ favorite part of this project has been delivering the products to healthcare providers.

On a recent delivery, one nurse told him it was like “a hospital Christmas.”

“You wouldn’t think to use something printed in my basement in a surgical setting, but here we are,” Bezos said.

Related Professionals

Related Industries

Receive insights from the most respected practitioners of IP law, straight to your inbox.

Subscribe for Updates